Formulating for sugar reduction in snack bars and energy bars is a common question our experts are asked since replacing sugar in a bar comes with unique challenges and requires a careful consideration of ingredients. For such product applications, we often turn to the prebiotic ingredient Isomalto-Oligosaccharide (IMO).

What is Isomalto-Oligosaccharide?

IMO is a sweet bulking syrup produced from starch using enzymes. In the US, it is no longer considered a fiber but rather a prebiotic ingredient (Canada, however, does still count it as a fiber). The syrup has 3 calories/gram, 0.75 carbs/gram, 0.075g of added sugar/gram, and is approximately 34% as sweet as sugar. The taste profile is fairly clean, particularly at lower use levels but high use levels may present a taste similar to that of pine needles. IMO is available from corn or tapioca sources and can be applied in syrup or powdered forms.

The Challenges of Sugar Reduction in Bars

Substituting sugar in a bar is much more complicated than substituting sugar in a beverage, where water can be used to replace sugar in a 100% formula. When removing syrups in a bar, the binding capability in a bar is impacted. Another hurdle when reformulating a bar is the need to maintain a 100% formula. One change in an ingredient’s percentage necessitates a need to change the percentage of the other ingredients in the formula.

Something that will also be important to consider in the formulation of a bar is shelf life — namely, stopping the bar from hardening. Choosing ingredients that do not tend to harden over time is essential. It’s recommended that close attention is paid to ingredients such as the syrups/binders, lecithin, gums, fibers, sugars, and the addition of glycerin or something similar that helps maintain softness.

Isomalto-Oligosaccharide (IMO) Formulation Example

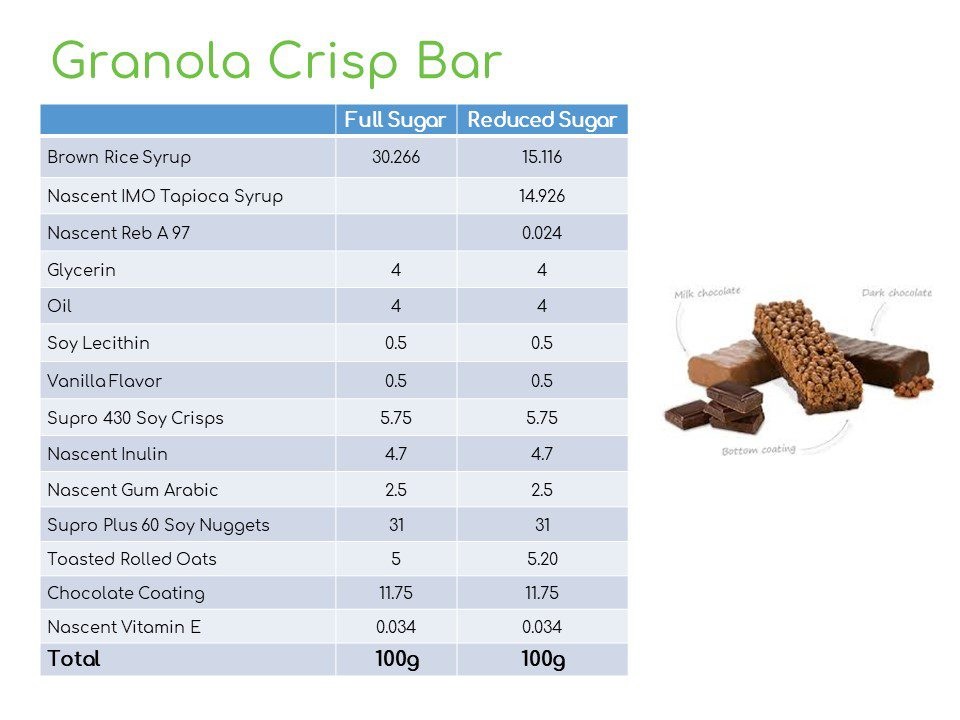

To solve for these challenges of reducing sugar in bars, IMO is an ideal sweetener to use. To illustrate IMO in action, we created a granola crisp bar as a sample formulation. In this bar, we removed 50% of the brown rice syrup and countered with the addition of IMO syrup, stevia, and some more of the toasted oats. A balance of binding capacity and dry ingredients needs to be considered when making these types of changes.

To calibrate our mix of sugar reduction ingredients, we experimented with multiple syrups including Howtian LLC’s allulose syrup and our other dietary fiber syrups. However, the other syrups didn’t have the binding capacity of the brown rice syrup and the bar fell apart more easily. If one were to formulate with a lower reduction goal than the 50% removal, the other syrups would likely be acceptable. In the findings from our testing though, Howtian LLC’s isomalto-oligosaccharide (IMO) exhibited the best binding capabilities, similar to that of brown rice syrup.

Additional Ingredients to Consider

When using a binder in bars, it can be very sticky and manufacturing customers will likely need measures to prevent the bar from sticking onto their rollers when producing at commercial scale. The addition of oil will help but you will then need to add an antioxidant to slow oxidation over shelf life. As part of our ingredients portfolio, Howtian LLC offers a patented Vitamin E which preserves the original α-tocopherol form for increased bioavailability. This can be added as a natural preservative for the oils in the bar.

Fiber is a common ingredient to be added to bars. Howtian LLC has multiple fibers that can be included in bar formulations. In our granola crisp bar example, inulin was chosen as it also helps with the binding capability.

Another common ingredient in bars is proteins. Soy is a popular choice among manufacturers for a plant-based protein. Howtian LLC can help identify other sources of protein powders such as pea or fava bean. Our technical teams regularly conduct thorough evaluations of top suppliers and can offer expertise on which powders offer the cleanest taste at a relatively low cost.

The delicious – and attractive – finishing touch for our bar is the chocolate coating. It can be drizzled on top, bottom coated, or fully enrobed. While the coating has a higher melting point than typical chocolate, a controlled-temperature distribution is likely needed to prevent the coating from melting during shipping.

Need the recipe for the granola crisp bar? Or ready to create your own formula? If you’re interested in learning more about formulating with Isomalto-Oligosaccharide (IMO), contact one of our expert consultants for your product development and formulation needs!