Consumer preferences for healthier, better-for-you products with less sugar content have driven significant innovation across the food and beverage industry in the last decade. Household names like Coca-Cola have reformulated, new brands like Halo Top and Bai Drinks have emerged, and diet trends like Keto have become mainstream. Although we’re seeing a proliferation of low-sugar and sugar-free alternatives from categories such as soft drinks, sports nutrition, dairy, and confectionary, there has been a considerable gap in the pace of adopting sugar reduction when it comes to baking. That is because sugar reduction in baked goods presents unique obstacles and can be costly compared to more simple, conventional reformulations. Achieving the perfect balance of sweetness, texture, and structural integrity requires a nuanced approach that traditional sugar alternatives often struggle to fulfill. However, things are starting to look up. With a growing number of successes, we’re now seeing manufacturers rise to the challenge and close the sugar reduction gap in baking.

Sugar Reduction on the Rise for Baking

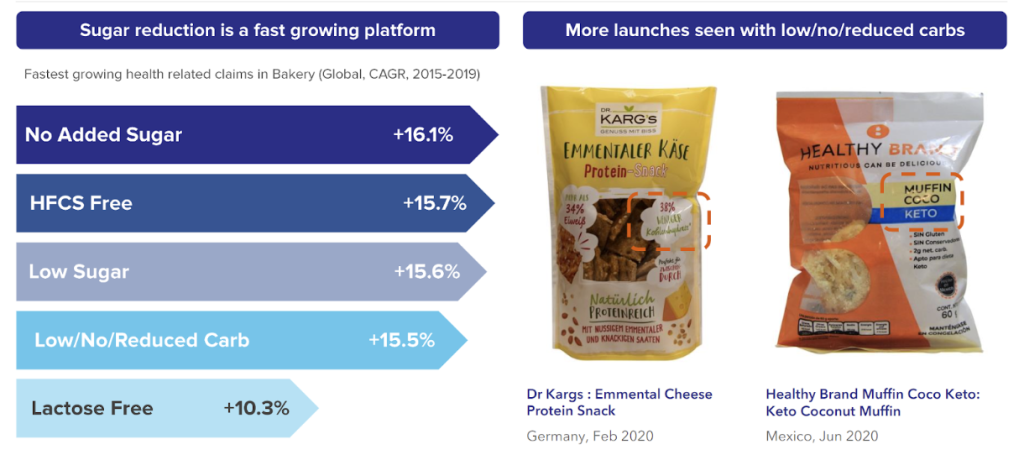

Research from Innova Market Insights on the baked goods industry shows that the four fastest growing product claims relating to health are all tied to sugar reduction. Despite the formulation challenges with replicating sugar, baked goods manufacturers are increasingly trying their hand at appealing to today’s consumers with claims such as low sugar, low carb and no added sugar.

In some cases, increasing government regulation is also playing a role in accelerating such initiatives. Many Latin American countries already have front-of-pack labelling with warnings for products that are high in saturated fat, sugar, and sodium. More recently, Canada has joined in mandating such labelling, with the regulation going into effect starting January of 2026. While this new mandate affects all food & beverage products, it is serving to jumpstart efforts from baking manufacturers in particular to catch up with other industries and prioritize sugar reduction.

Notable examples of brands and products that have successfully reduced sugar in baked goods include Pillsbury, Quest, Catalina Crunch and Birch Benders.

Pillsbury™ Zero Sugar Moist Supreme Yellow Premium Cake Mix

Pillsbury™ Moist Supreme® Yellow Cake Mix, a classic favorite, has 19 grams of added sugar per package. However, the Zero Sugar Moist Supreme® Classic Yellow Premium Cake Mix is a shining example of product innovation, replacing all 19 grams of sugar with maltitol and non-nutritive high-intensity sweeteners. The high-intensity sweeteners are particularly essential in making up for the sweetness where maltitol falls short, but without compromising on taste or quality. Ultimately, this leads to a reduction of 20 calories as packaged.

Keto-Friendly Quest Nutrition®, Birch Benders and Catalina Crunch

Quest Nutrition® favorites like Chocolate Chip Protein Cookies use a blend of erythritol and stevia to provide not just sweetness, but also other key properties that sugar traditionally provides in baking such as structure and browning. This type of blend is often found in keto recipes, where eliminating carbs is the main objective. Birch Benders uses the same concept for its Keto Ultimate Fudge Brownie, although their blend consists of not just erythritol and stevia extract, but also monk fruit. Catalina Crunch is another popular keto-friendly brand with its product line of cookies and cereals. However, unlike Quest, Catalina Crunch cookies still utilize some sugar – albeit at a low amount of one gram per cookie. On the other hand, Catalina Crunch cereal uses only stevia extract and monk fruit to replicate the sweetness of sugar.

Common Challenges to Reducing Sugar in Baked Goods

One of the primary obstacles in sugar reduction lies in preserving the desired sweetness and mouthfeel of baked goods. Traditional sugar imparts sweetness but also contributes to texture, browning, and moisture retention. Altering these characteristics without compromising taste and quality requires a more tailored approach. Alternative sweeteners such as stevia, allulose, and erythritol offer promising avenues for sugar reduction. Allulose, for instance, boasts a similar taste profile to sucrose at a fraction of the calories, making it an attractive option for health-conscious bakers. Similarly, erythritol provides sweetness without the glycemic impact of sugar, offering versatility in recipe formulation.

There is ever-increasing opportunity for sugar-reduced options in the baking category. A recipe for success with sugar reduction typically consists of a few key guidelines and principles for baking.

Key Formulation Guidelines for Sugar Reduction in Baking

Understand the Roles of Sugar

Typically, the first thing that comes to mind regarding sugar is sweetness. However, sugar has more functions than sweetening when used in baking applications. Sugar is also important in baking for the key functions of rising, browning, and structure – all of which have to be considered when looking to reduce or replace sugar from a recipe.

Rising

Sugar helps with rising whether it be in cakes and quick breads or baked goods with yeast. In cake batters, the sugar crystals create air bubbles that lighten the batter and when baked, expand and lift the batter, causing it to rise. This is why the ratio of sugar is important. Too much sugar will cause the batter to weigh down and limit its ability to rise. Not enough sugar will cause the cake to deflate after baking due to the lack of structural support. When replacing sugar in a recipe, it is important to use sugar alternatives that can equally substitute the volume of sugar taken out.

Structure

Sugar loves to bond to water. This bond determines how tall our breads rise or how much our cookies spread. Sugar bonding with water prevents starches and proteins in the flour from binding to that moisture, causing gluten development to slow down. The diminished gluten development gives the baked good a softer texture and prevents it from drying out. The right balance of gluten, starch, and sugar determines if you will have a soft or dense baked good. To put this into perspective, too much sugar will lead to a floppy loaf of bread or too little sugar will lead to a bread with consistency more similar to that of a pretzel roll.

Browning

Those in the food industry will be familiar with the Maillard Reaction, the browning effect produced during the baking process. This golden-brown color we want to see on our bread comes from sugar caramelizing at high temperatures. The more sugar, the darker the color of the browning.

To reproduce browning, a commonly used replacement method is adding a combination of erythritol and allulose. These ingredients, coupled with stevia to bring the sweetness up to par, are great pairings that have proven effective. Considerations to keep in mind when using erythritol and allulose to reduce sugar include the duration of baking, heat, and browning. Allulose tends to brown faster than sugar, so time and temperature need to be adjusted as necessary. Additionally, erythritol does not brown nor does it give a soft and chewy texture when used at high concentrations. This is due to erythritol being hydroscopic. It works well in baked goods that already have a high moisture content, such as cheesecakes.

Key Ingredients for Sugar Reduction in Baking

Bulking Agents

There are many different bulking agents to choose from depending on what requirements and labelling standards you may be looking to achieve. Common ones include sugar alcohols, rare sugars, soluble fibers, and inulin.

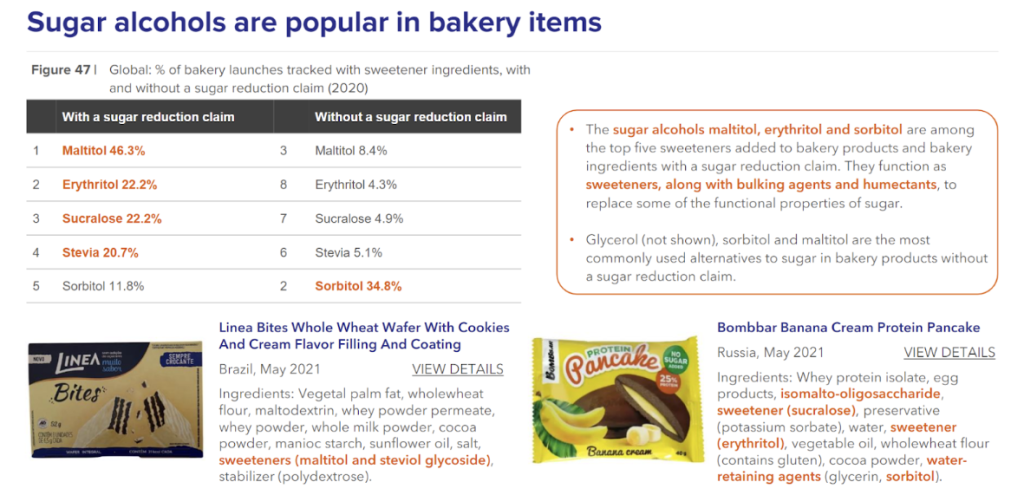

Maltitol, erythritol, and sorbitol are common ingredients used in bakery items due to their sweetening and humectant properties. Maltitol is a sugar alcohol that is commonly used as a sugar alternative and has less of the cooling effect that is more commonly associated with erythritol and xylitol. Allulose, a rare sugar, has also been an increasingly popular ingredient, especially given that allulose has browning capabilities which can mimic the Maillard browning from sugar.

Another aspect in choosing a bulking agent is whether a clean label or natural ingredients are important claims to the product. In such cases, using dietary fibers for bulking and binding is a popular choice considering they have a low impact on glycemic index. These are best used in combination with a high intensity sweetener like stevia or monk fruit since most soluble fibers provide only a little bit of sweetness.

High Intensity Sweeteners

High intensity sweeteners like stevia perform differently in baked applications than in other applications. The bitterness or off-notes threshold for stevia in baked applications is much higher than for beverage or dairy applications, usually double or triple the amount. Although solubility is not as much of a concern in baked applications compared to beverages, heat stability should be taken into consideration. Certain rebaudiosides like Reb D and Reb M are only heat stable up to 354°F and 284°F respectively, while Reb A can be heat stable up to 390°F.

Baked applications made with stevia and other polyols or fibers require a more skillful balance of ingredients as well as manufacturing processes. The same technique used in a cake with sugar must be adapted to accommodate for the differences that the sugar alternatives bring.

Sugar Reduction Does Not Mean Sugar-Free

Sugar alternatives can mimic certain characteristics of sugar but there is no singular solution to replacing sugar and all its functional properties. A product that completely eliminates sugar sacrifices taste in many cases. An effective sugar reduction strategy does not come at the complete expense of the product’s taste, texture, shelf life, and ultimately, consumer satisfaction.

When you consider the challenges and complexities, fully replacing sugar in baking is not always feasible. Although it may seem counterintuitive, leaving some sugar in the formulation is highly effective at achieving sugar reduction objectives without compromising on taste and quality. After all, many baked products are still meant to be indulgent. Rather than replace sugar entirely, you may be more successful by leveraging a suite of sugar reduction ingredients to reduce calories and eliminate some percentage of sugar while still maintaining a taste profile that matches consumer expectations.

A Healthier Future Ahead for Baking

The ongoing evolution of sugar reduction in baking presents promising advancements that align with modern consumer expectations for healthier yet indulgent treats. As the demand for lower sugar content in food and beverages continues to rise, the baking industry is poised to innovate with ingredients and techniques that maintain the desired taste, texture, and appearance of baked goods. By embracing these advancements, bakers can meet the growing consumer preference for healthier options without compromising on quality. The future of baking lies in striking this delicate balance, ensuring that reduced sugar formulations become the new standard in kitchens and bakeries around the world. As this trend gains momentum, we can anticipate a healthier, yet equally satisfying, future for our favorite baked goods.

Through a combination of scientific expertise and formulation innovation, HOWTIAN partners with our baking customers to achieve optimal results in sugar reduction. To learn more about partnering on your next project, get in touch with one of our specialists today.